我们原有的铣头自动转程序不能限制转头区域限制,在小于650,大于3450的区域头在原地转,导致头的角度乱了。

我在想要能过读取Y的当前位置加到子程序才行,可是我知道地址,咨询SIEMENS知道是$AA_IM【Y】

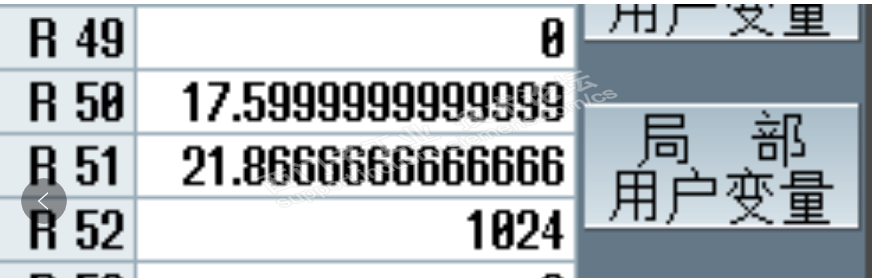

我就测试读到R参数内试试

确实是当前坐标位置

开始改子程序

N10 DEF INT AFF_STADUS

N11 DEF REAL ROT2

N12 DEF REAL ROT0

N13 DEF REAL ROT5

N14 DEF REAL ROT6

N15 DEF REAL ROT1

N16 DEF REAL ROT3

N20 AFF_STADUS=$A_DBB[1]

M80

G4F1

IF $AA_IM[Y]<650 GOTOF _END

IF $AA_IM[Y]>3450 GOTOF _END

G4F1

N30 CASE AFF_STADUS OF 2 GOTOF LA1 DEFAULT GOTOF LABBLE_6

N40 LA1:M80

;N50 G0G53Y2100Z0

N60 G4F1

ROT2=DEG

ROT0=DEG_ACTUAL

ROT1=DEG_ACTUAL

N70 M09

N80 M40

N90 M41

N100 G4F1

N110 M98

N120 G4F1

N130 STOPRE

N140 M05

N150 G4F1

N160 IF ROT2==ROT0 GOTOF LABBLE_6

N170 ROT5=(ROT2/2.5)

N180 STOPRE

N190 ROT6=ROUND(ROT5)

N200 STOPRE

N210 IF ROT5<>ROT6 GOTOF LABBLE_5

N220 SPOS=ACP(ROT1);SPINDLE OFFSET

N230 G4F1

N240 M80

N250 M95

N260 MSG("齿牙盘松开")

N270 M75

N280 STOPRE

N290 G4F5

N300 IF (ROT2-ROT0+ROT1)>360 GOTOF LABBLE_1

N310 IF (ROT2-ROT0+ROT1)<0 GOTOF LABBLE_2

N320 IF 0<(ROT2-ROT0+ROT1)<360 GOTOF LABBLE_3

N330 LABBLE_1:ROT3=ROT2-ROT0+ROT1-360

N340 GOTOF LABBLE_4

N350 LABBLE_2:ROT3=ROT2-ROT0+ROT1+360

N360 GOTOF LABBLE_4

N370 LABBLE_3:ROT3=ROT2-ROT0+ROT1

N380 GOTOF LABBLE_4

N390 LABBLE_4:FA[S1]=DEG_FEED

N400 SPOS=ACP(ROT3);DISTANCE TO GO

N410 STOPRE

N420 ROT0=ROT2;CURRENT POSITION

N430 DEG_ACTUAL=ROT3

N440 G4F1

N450 M96

N460 MSG("齿牙盘油缸夹紧")

N470 G4F1

;N480 M76

N490 STOPRE

N500 FA[S1]=0

N510 M98

N520 G4F1

N530 M40

N540 GOTOF _END

N1060 LABBLE_6:MSG("附件头信号错误")

N1070 M99

N1080 LABBLE_5:STOPRE

N1090 MSG("设定的旋转度数不对")

N1100 GOTOF _END

N1110 LABBLE_6:STOPRE

N1120 MSG("目标旋转度数与当前度数重合")

N1130 GOTOF _END

N1140 _END:

N1150 MSG( )

N1160 RET

红色部份是我加的, 经过测试完美,转头角度也不乱了。