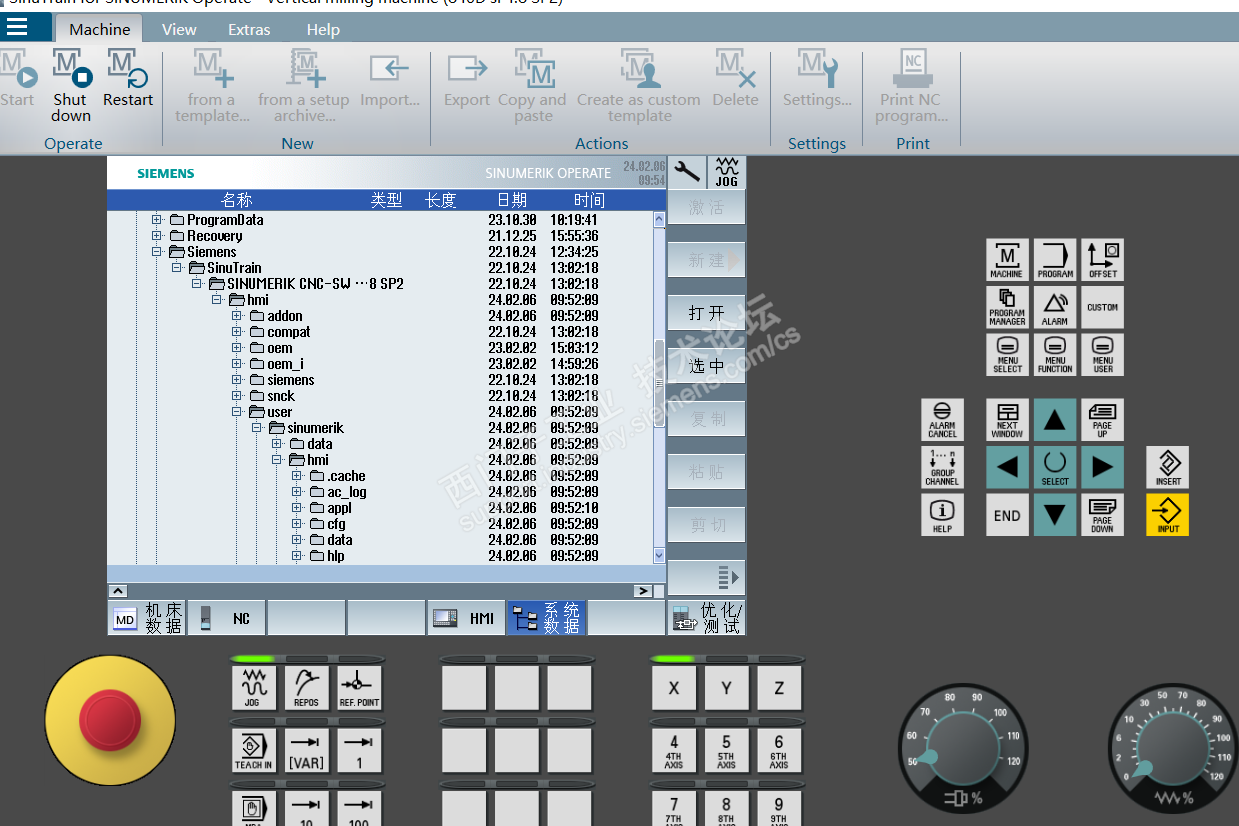

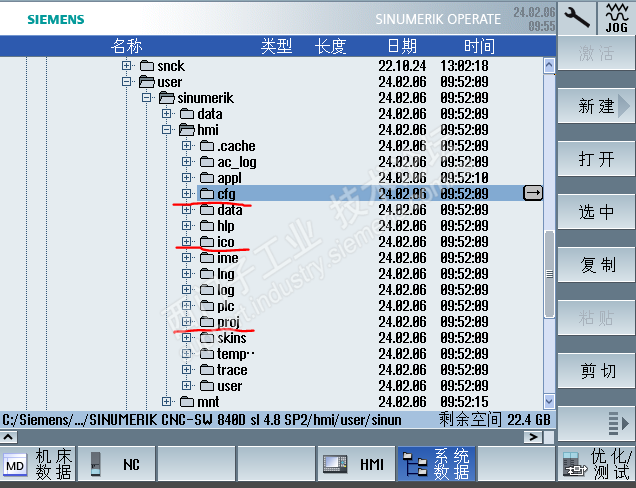

首先把制作好的文件CUSTOM.INI和EASYSCREEN.INI,拷到CFG目录下,把LOGO.PNT,NL.BMP,SPLASH.PNT拷到ICO目录的640内,把CUSTOM.COM文件拷到PROJ目录内。

CUSTOM.INI文件内容如下:

; Text on the caption bar of the form in the start screen

[Header]

Text=Custom

; Picture shown on the form in the start screen

[Picture]

Picture=NL.bmp

EASYSCREEN.INI文件内容如下:

[STARTFILES]

StartFile02 = area := Custom, dialog := SlEsCustomDialog, startfile := CUSTOM.COM

CUSTOM.COM文件内容如下:

//S(Start)

HS1=("主菜单")

PRESS(HS1)

LM("MASK1")

END_PRESS

//END

//M(MASK1/"输入信号"/)

DEF Var1=(B///,"主轴低档0/1",,/wr1//"I1.0"/10,20,180/180,20,20,//),

DEF Var2=(B///,"主轴高档0/1",,/wr1//"I1.1"/10,40,180/180,40,20,//),

DEF Var3=(B///,"导轨润滑过载0/1",,/wr1//"I1.2"/10,60,180/180,60,20,//),

DEF Var4=(B///,"主轴风机过载0/1",,/wr1//"I1.3"/10,80,180/180,80,20,//),

DEF Var5=(B///,"提升电机过载0/1",,/wr1//"I1.4"/10,100,180/180,100,20,//),

DEF Var6=(B///,"卷屑1电机过载0/1",,/wr1//"I1.5"/10,120,180/180,120,20,//),

DEF Var7=(B///,"卷屑2电机过载0/1",,/wr1//"I1.6"/10,140,180/180,140,20,//),

DEF Var8=(B///,"冷却电机过载0/1",,/wr1//"I1.7"/10,160,180/180,160,20,//),

DEF Var9=(B///,"刀库电机过载0/1",,/wr1//"I3.6"/10,180,180/180,180,20,//),

DEF Var10=(B///,"刀臂电机过载0/1",,/wr1//"I3.7"/10,200,180/180,200,20,//),

DEF Var11=(B///,"刀库原位0/1",,/wr1//"I4.0"/10,220,180/180,220,20,//),

DEF Var12=(B///,"刀库计数0/1",,/wr1//"I4.1"/10,240,180/180,240,20,//),

DEF Var13=(B///,"刀臂原位0/1",,/wr1//"I4.2"/10,260,180/180,260,20,//),

DEF Var14=(B///,"扣刀确认0/1",,/wr1//"I4.3"/10,280,180/180,280,20,//),

DEF Var15=(B///,"刀臂停止位0/1",,/wr1//"I4.4"/10,300,180/180,300,20,//),

DEF Var16=(B///,"刀套垂直0/1",,/wr1//"I4.5"/10,320,180/180,320,20,//),

DEF Var17=(B///,"刀套水平0/1",,/wr1//"I4.6"/10,340,180/180,340,20,//),

DEF Var18=(B///,"紧急停止0/1",,/wr1//"I0.0"/210,20,180/320,20,20,//),

DEF Var19=(B///,"空气压力0/1",,/wr1//"I0.1"/210,40,180/320,40,20,//),

DEF Var20=(B///,"润滑液位0/1",,/wr1//"I0.2"/210,60,180/320,60,20,//),

DEF Var21=(B///,"润滑压力0/1",,/wr1//"I0.3"/210,80,180/320,80,20,//),

DEF Var22=(B///,"松刀按钮0/1",,/wr1//"I0.4"/210,100,180/320,100,20,//),

DEF Var23=(B///,"主轴松开0/1",,/wr1//"I0.5"/210,120,180/320,120,20,//),

DEF Var24=(B///,"主轴夹紧0/1",,/wr1//"I0.6"/210,140,180/320,140,20,//),

DEF Var25=(B///,"油冷故障0/1",,/wr1//"I0.7"/210,160,180/320,160,20,//),

HS1=("输入信号")

HS2=("输出信号")

HS3=("调试画面")

PRESS(HS2)

LM("MASK2")

END_PRESS

PRESS(HS3)

LM("MASK3")

END_PRESS

//END

//M(MASK2/"输出信号"/)

DEF Var26=(B///,"EP上电0/1",,/wr1//"Q0.3"/10,20,180/180,20,20,//),

DEF Var27=(B///,"主轴松刀0/1",,/wr1//"Q0.4"/10,40,180/180,40,20,//),

DEF Var28=(B///,"主轴低档0/1",,/wr1//"Q0.6"/10,60,180/180,60,20,//),

DEF Var29=(B///,"主轴高档0/1",,/wr1//"Q0.7"/10,80,180/180,80,20,//),

DEF Var30=(B///,"主轴吹气0/1",,/wr1//"Q1.0"/10,100,180/180,100,20,//),

DEF Var31=(B///,"主轴气冷0/1",,/wr1//"Q1.1"/10,120,180/180,120,20,//),

DEF Var32=(B///,"导轨润滑0/1",,/wr1//"Q1.2"/10,140,180/180,140,20,//),

DEF Var33=(B///,"提升正转0/1",,/wr1//"Q1.3"/10,160,180/180,160,20,//),

DEF Var34=(B///,"提升反转0/1",,/wr1//"Q1.4"/10,180,180/180,180,20,//),

DEF Var35=(B///,"卷屑1电机0/1",,/wr1//"Q1.5"/10,200,180/180,200,20,//),

DEF Var36=(B///,"卷屑2电机0/1",,/wr1//"Q1.6"/10,220,180/180,220,20,//),

DEF Var37=(B///,"冷却电机0/1",,/wr1//"Q1.7"/10,240,180/180,240,20,//),

DEF Var38=(B///,"刀库正转0/1",,/wr1//"Q3.0"/10,260,180/180,260,20,//),

DEF Var39=(B///,"刀库反转0/1",,/wr1//"Q3.1"/10,280,180/180,280,20,//),

DEF Var40=(B///,"刀臂旋转0/1",,/wr1//"Q3.2"/10,300,180/180,300,20,//),

DEF Var41=(B///,"刀套向上0/1",,/wr1//"Q3.3"/10,320,180/180,320,20,//),

DEF Var42=(B///,"刀套向下0/1",,/wr1//"Q3.4"/10,340,180/180,340,20,//),

;DEF Picture1=(S///,"\\CCJ2.PNG",,/wr1///50,50,330,210/460,200,0,//),

HS1=("输入信号")

HS2=("输出信号")

HS3=("调试画面")

VS8=("退出")

PRESS(VS8)

EXIT

END_PRESS

PRESS(HS1)

LM("MASK1")

END_PRESS

PRESS(HS3)

LM("MASK3")

END_PRESS

//END

//M(MASK3/"调试画面"/)

DEF Title1=(S///,"此画面仅在调试中使用",,/wr1///30,0,160/180,0,80,//),

DEF Var111=(B///,"调试允许0/1",,/wr2//"db9002.dbx1.0"/10,20,180/160,20,20,//),

DEF Var112=(B///,"确认调试0/1",,/wr2//"db9002.dbx1.1"/300,20,180/460,20,20,//),

DEF Var113=(B///,"强制松附拉钉0/1",,/wr2//"db9002.dbx1.2"/10,40,180/160,40,20,//),

DEF Var114=(B///,"强制紧附拉钉0/1",,/wr2//"db9002.dbx1.3"/10,60,180/160,60,20,//),

DEF Var115=(B///,"强制松主轴0/1",,/wr2//"db9002.dbx1.4"/10,80,180/160,80,20,//),

DEF Var116=(B///,"强制紧主轴0/1",,/wr2//"db9002.dbx1.5"/10,100,180/160,100,20,//),

DEF Var117=(B///,"强制松鼠牙盘0/1",,/wr2//"db9002.dbx1.6"/10,120,180/160,120,20,//),

DEF Var118=(B///,"强制紧鼠牙盘0/1",,/wr2//"db9002.dbx1.7"/10,140,180/160,140,20,//),

HS1=("输入信号")

HS2=("输出信号")

HS3=("调试画面")

VS8=("退出")

PRESS(VS8)

EXIT

END_PRESS

PRESS(HS1)

LM("MASK1")

END_PRESS

PRESS(HS2)

LM("MASK2")

END_PRESS

//END

测试结果:

用Sinu Train的好处是不用到现场上试,尤其是调整文本合适位置比较方便。